Model Kit

Reduce Steps, Save Time, Cut Cost.

Kits for Digital Denture Milling of Partial-Dentures, Full-Dentures, and Model Creation

Removable Denture Kit

CA -DK1

$1,699 CAD

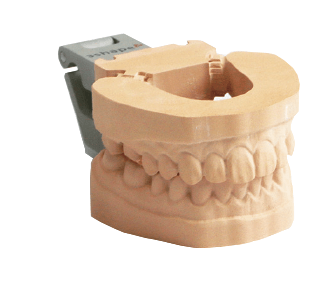

Model Kit

CA -MK1

$1,699 CAD

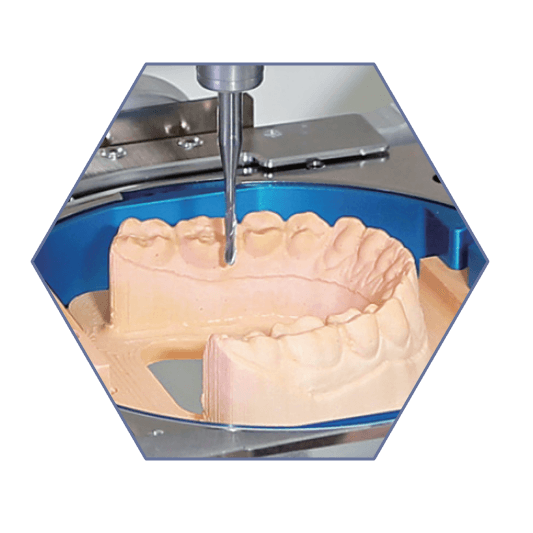

With Time Reduction Kits (TRK) from DGSHAPE, produce molded gypsum or acrylic based materials for accurately milling partial or full-denture bases, as well as models, using your DWX-52D, 52DC, and 52DCi dental mill.

- Removable Denture Kit reduces in-house finishing time for full dentures and partial denture applications

- Affordable materials combine with precision denture milling for a more cost-effective and accurate solution

- The TRK digital workflow saves time and cost when compared to traditional and 3D printing methods

Model Kit

CA-MK1

Using a kit that includes specially-designed silicone molds— pour, cure and harden gypsum material to create material discs for milling with DWX devices.

Mix & Pour

Measure gypsum and water in a container, mix and pour into a full-arch or quadrant silicone mold.

Cool

Wait for the mixture to harden and then remove the hardened gypsum material disc from the silicone mold.

Mill

Set the material disc in the TRK fixture and place the fixture in a milling adapter to mill a model on a DWX device.

Kit Includes

Full-Arch Silicone Mold

3 Full-Arch Molds

With your choice of gypsum materials, create full-arch gypsum discs for milling.

Quadrant Silicone Mold

3 Quadrant Molds

With your choice of gypsum materials, create partial gypsum discs for milling.

TRK Fixtures

3 Fixtures

Special fixtures allow gypsum disc insertion into your disk adapters.

Leveling Spatula

1 Spatula

Create a level surface on your mold after pouring the plaster.

2.0mm Flat End Carbide Tool

1 Tool (ZRB-100D)

A specially designed burr to significantly reduce roughing time with DWX technologies.